Principle and technical details

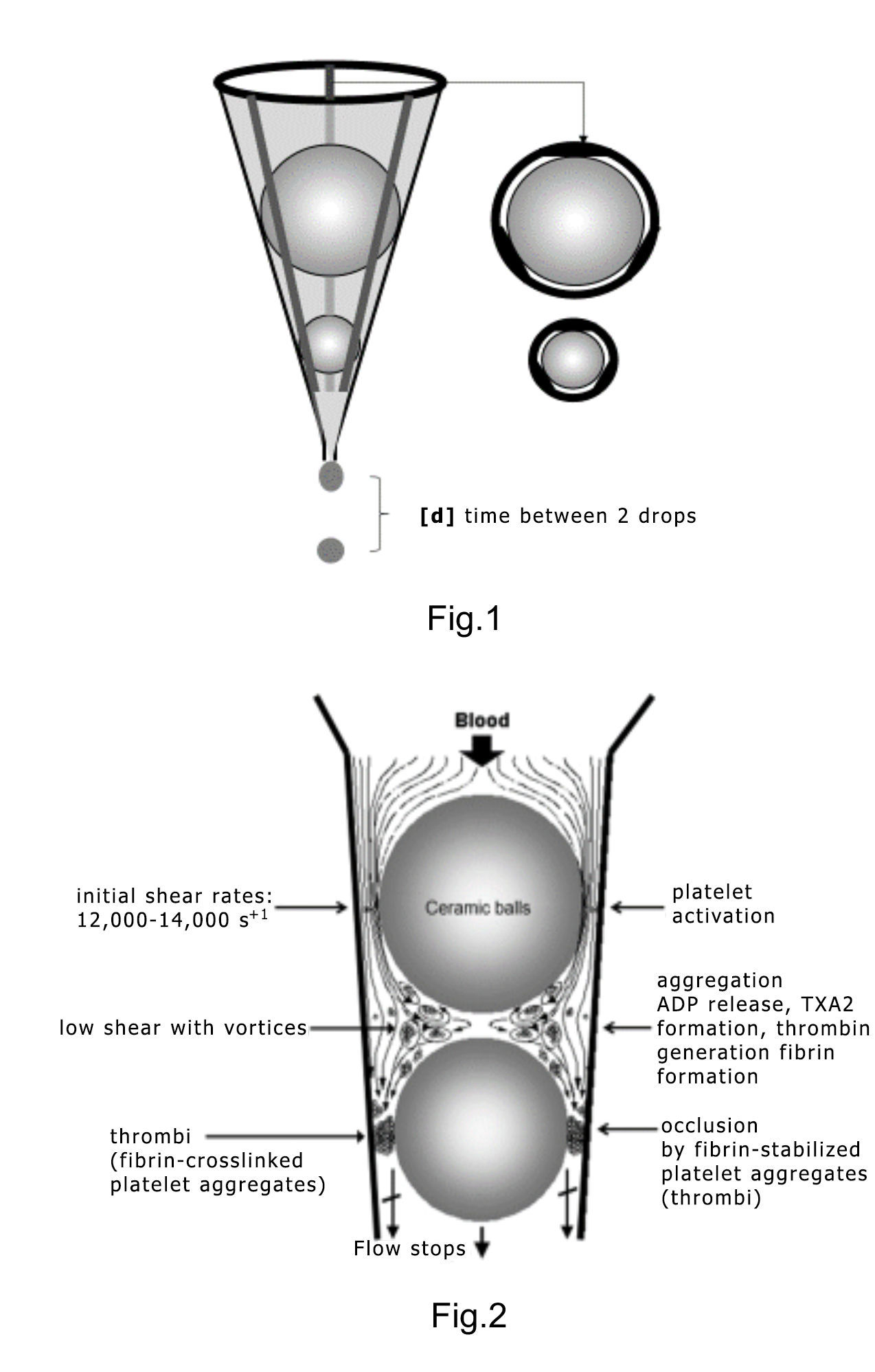

The test tube (Figure 1) has a conical section in which two ceramic ball bearings are situated. Because of three flat segments formed on the inner surface of the tube, three narrow gaps exist adjacent to the ball bearings.

When blood is added to the tube, it flows through the narrow gaps by the ball bearings and the droplets are collected in a reservoir downstream. Passing through the gaps by the upper (larger) ball bearing, platelets are exposed to high shear stress and become activated.

In the space between the ball bearings, platelet aggregates are formed and thrombin is generated from the activated platelets. As the fibrin-stabilized thrombi reach and gradually occlude the gaps by the lower ball bearing, blood flow is reduced and then arrested.

The instrument detects the time interval (d, sec) between two consecutive blood drops falling into the reservoir. At the start of the test, flow is rapid and hence (d) is small. Subsequently, the flow rate decreases and hence (d) increases.

When the actual default d ≥10 sec is reached, this time (T1) is displayed as Occlusion Time (OT sec). Subsequently the flow is completely arrested.

After OT, a preset “thrombi stabilization period” follows (typically set to 300 sec), during which the sensors ignore counting the blood drops. This time allows stabilization of the fully occlusive thrombi. Eventually, due to endogenous thrombolysis, flow is partially restored as indicated by detection of the first blood drop after OT (T2). This is recorded as the Lysis Time (LT sec).